[CODE_4]: MEDIA_ELEMENT_ERROR: Format error

무상 교체 부품

무상 교체 부품

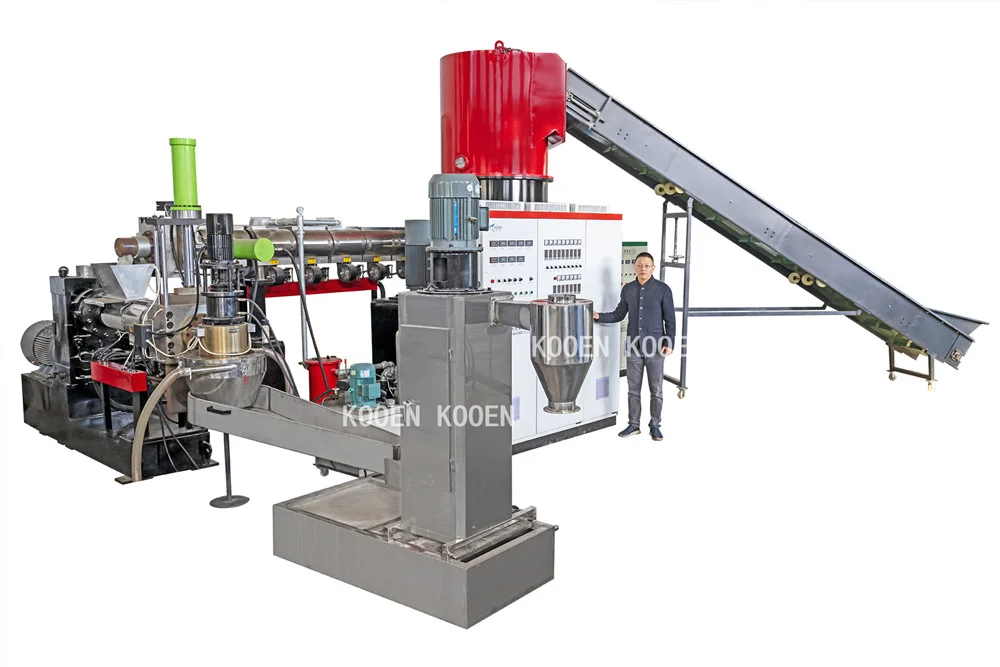

Model | CAPACITY (kg/h) | POWER CONSUMPTION (kw) | WATER CONSUMPTION (ton/h) | Manpower | HUMIDITY CONTENT |

MT-300 | 300kg/hour | 150kw | 3ton/h | 4 | <1% |

MT-500 | 500kg/hour | 230kw | 4-5ton/h | 4 | <1% |

MT-1000 | 1000kg/hour | 270kw | 6-7ton/h | 5-6 | <1% |

MT-2000 | 2000kg/hour | 370kw | 8ton/h | 5-6 | <1% |

MT-3000 | 3000kg/hour | 420kw | 10ton/h | 7 | <1% |

Cooig.com에서 진행하는 모든 결제는 엄격한 SSL 암호화 및 PCI DSS 데이터 보호 프로토콜을 통해 보호됩니다

주문한 상품이 배송되지 않거나, 누락되었거나, 제품에 문제가 있는 상태로 도착하는 경우 환불을 청구하세요